Disassembling end-of-life batteries

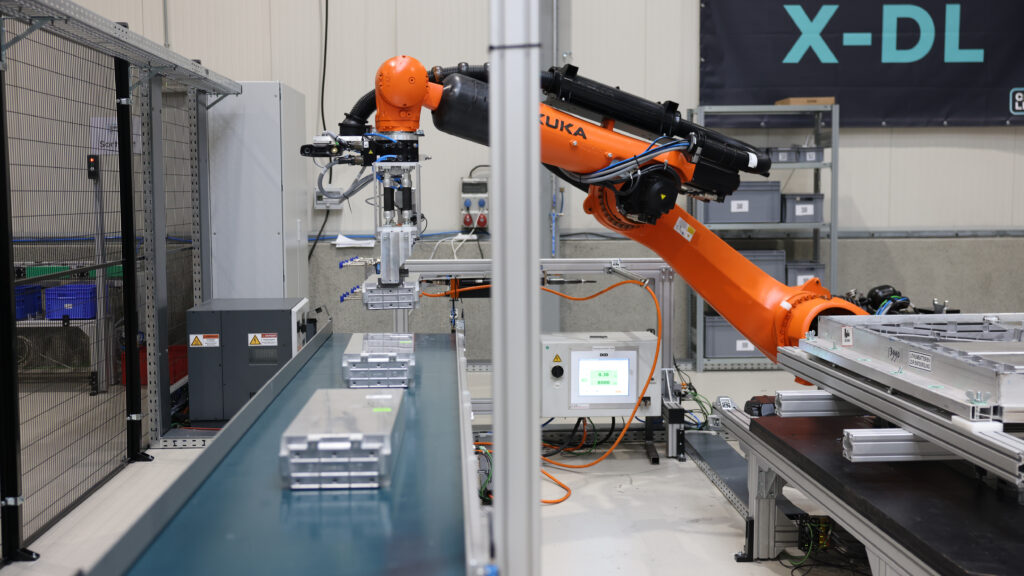

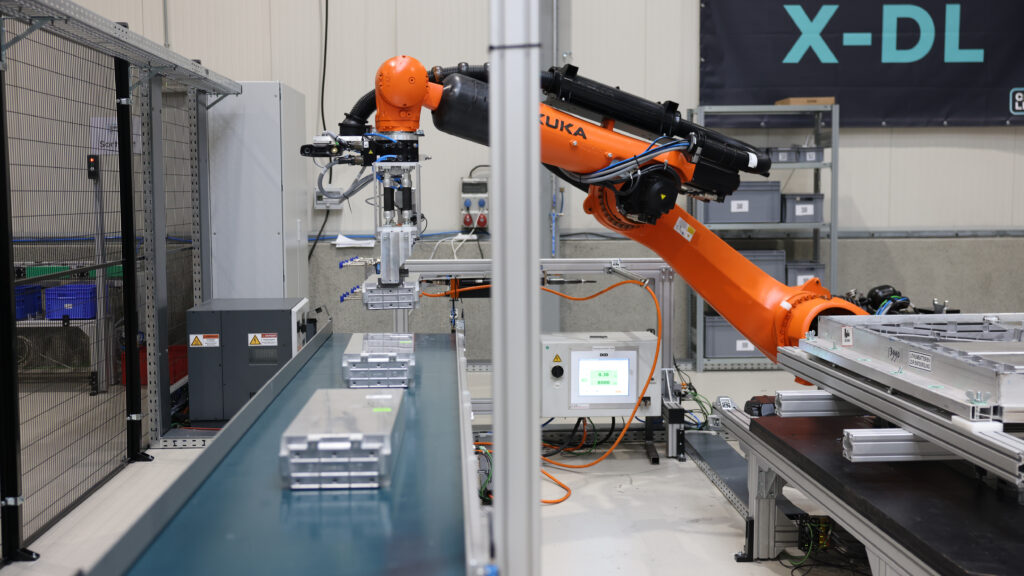

Circu Li-ion, a Luxembourg-based startup, is building the future of automation with a robot that breaks apart lithium-ion batteries to recycle and re-use the components.

Circu Li-ion, a Luxembourg-based startup, is building the future of automation with a robot that breaks apart lithium-ion batteries to recycle and re-use the components.

In 2022, the global demand for lithium-ion (li-ion) batteries grew by 65%, and this is only projected to continue increasing by 30% per annum until the end of the decade.

Around 80% of this increase is for use in electric vehicles. While some electric vehicle batteries have a second life in static, less demanding applications, eventually all require disassembly, a process that is inefficient, labour-intensive and hazardous.

“Dissassembly is dull, dangerous and dirty”, in the words of Dr. Xavier Kholl, co-founder and Chief Technology Officer of Circu Li-ion. “Touch the wrong part of a lithium-ion battery and you die”. Conscious of these pressing safety concerns, Luxembourg-based startup, Circu Li-ion, is working to apply robotics and reinforcement learning to recover scarce critical materials, principally lithium, from end-of-life batteries cleanly, safely and at scale, in a developing regulatory environment.

Under the aegis of the Eurostars LAMBDA project run by the Swiss Battery Technology Center in Bern, Switzerland, Circu Li-ion partnered with AICA to achieve higher robot autonomy for the process, while cleanly recovering 95% of battery components at a 47% cost saving.

"By its nature, an efficient and electrified economy must also be an efficient circular economy." Kohll

Circu Li-ion is also teaching its robots to learn how to disassemble batteries and other devices, thus creating an intelligent technology for “agnostic disassembly”. Even within an electric vehicle, the battery is not the only component of value; a drive train contains valuable magnets, for example.

Beyond electric vehicles, computers and even vacuum cleaners are potentially suitable for up-cycling, bringing a workable circular economy ever closer.

A robot arm and hand can be mechanically adapted to perform specialised and repeated tasks, but when combined with camera eyes and a software brain it can intelligently adapt itself to unlock more general capabilities. The control software developed by Circu Li-ion and AICA allows robots to practice and learn new behaviours in a simulation environment before transferring them to hardware. With a sense of touch provided by a force sensor, robot actions become delicate and precise even when parts are in uncertain positions. These new capabilities can be combined and deployed faster and with less experience through modular programming and generative AI to accelerate the rollout of new workflows and lines.

"Protesting about an issue can have an impact, but solving the issue will always have a far greater one." Paraphrased by Dr. Kohll from Professor Dr. Wendelin Jan Stark

Kohll remembers the moment when these words first appeared before his eyes on a screen in a lecture theatre in Zurich. Professor Stark was then one of the youngest professor at ETH Zurich, and the message stayed with Kohll.

Born and raised in Luxembourg, Kohll undertook his higher education in Switzerland, taking his PhD in chemical engineering and soft robotics. Talking with him, it is clear that his education spanning both the micro and macro suits the world of startups.

An enthusiastic and successful team builder, Kohll is keen to emphasise that Circu Li-ion's impressively rapid progress is down to its collaborative international partnerships, described by Kohll as natural and seamless.

"It is easy to talk about doing good things," he says, "but much harder to do them." So while Circu Li-ion's mission is to lead the urban mining revolution, it is doing so by working to bridge what he calls “the simulation to reality gap”.

"The future of automation lies in making it sufficiently flexible and adaptable. We need to enable robots not just to learn, but to learn how to disassemble a wide variety of batteries, and in time, other things, efficiently and at scale." Kohll

The automation of disassembly is certainly a good thing. It is an effective way of husbanding scarce critical materials whilst building future capacity. It creates value from what has hitherto been considered waste, reduces pollution and protects the environment. And it strengthens our economies and our energy security.

Were you inspired by this story and have a project idea you want to realise?

Through our funding programmes, national/regional funding bodies support SMEs, large companies, universities and research organisations conducting R&D and innovation projects together beyond borders to achieve great results. Learn more about our programmes and discover whether we have a funding opportunity for your organisation.

Eureka programme and project name: Eurostars-3 LAMBDA

Countries involved: Luxembourg, Switzerland

Project duration: 2023-2025