Eat 3D to save fish

An Austrian startup, Revo Foods, has developed a pioneering method to 3D print vegan salmon fillets. The company is paving the way for a revolution in how we eat to reduce our ecological impact.

An Austrian startup, Revo Foods, has developed a pioneering method to 3D print vegan salmon fillets. The company is paving the way for a revolution in how we eat to reduce our ecological impact.

Doctors and environmentalists are increasingly on the same side: they recommend we reduce the amount of red meat and mercury-containing fish we eat and opt for more plant-based meals. An international commission, for instance, has recommended a “planetary health diet” as a win-win way to reduce many diseases and the impact of intensive farming on the climate, saying Europeans should eat 77% less red meat and North Americans 84% less.

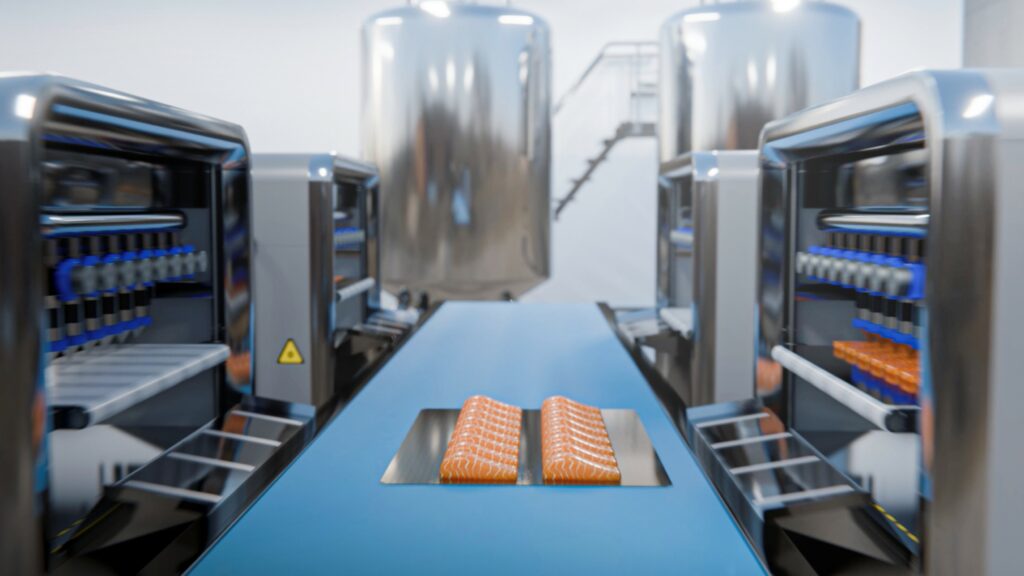

This amounts to a revolution to the food served up in homes and restaurants in high-income countries. An Austrian startup believes eating less meat and fish does not need to feel like a sacrifice. Revo Foods has developed a 3D printing technology to produce the first vegan fish-tasting fillets on an industrial scale. “We have a new process that combines two different materials in a complex shape and structure,” explains founder and chief executive Robin Simsa. “It allows us to print protein fillets that have a completely new feel in the mouth.”

Revo Foods’ vegan protein fillets taste like roast salmon, but customers can eat without worrying about sustainability since the fish is made up of mycelium-based mycoprotein. Thanks to research funding provided through the Eurostars programme, Revo Foods developed the mushroom-based protein with Swedish mycoprotein producer Mycorena.

The mycoprotein used to create the salmon fillets comes from mushroom roots and is grown in a fermenter with sugar and minerals. “The mushroom roots are placed in a liquid suspension, which gives a high yield, taking up little space. The controlled conditions ensure the quality and cleanliness of the product,” says Simsa. These are huge benefits compared to land-intensive, carbon-intensive animal production: livestock agriculture takes up to 35% of habitable land on the planet and accounts for 70% of food-related emissions in high-income nations.

With Revo Foods’ method, microalgae oil, which has a high fibre content, is integrated into the protein fibres as they are printed by the 3D machine. Mycorena’s expertise was crucial for developing a mycoprotein that would not clog up Revo Foods’ 3D printers.

Bought in August by Belgian food producer Naplasol, Mycorena had received funding from the European Space Agency’s (ESA) Discovery Programme in recognition of its products’ potential for long-distance space missions. “Mycorena was invaluable because there is a lot involved in the pre-processing, post-processing and handling of the mycelium-based mycoprotein,” notes Simsa.

The two partners tested and refined the mycoprotein and shaped and printed fillets made from it. During the one-year collaboration, the companies managed to print a few-thousand special edition fillets that they marketed as “the filet, inspired by salmon”, selling them through a vegan supermarket in Vienna and online. “We got a 4.7-star rating online and we have gathered suggestions to even further improve the salmon taste and texture,” says Simsa.

German grocery chain, REWE, signed up to start selling “inspired by salmon” in its Austrian supermarkets from October, a breakthrough for a startup of 35 people, paving the way for other “inspired by…” faux fish products. Europeans can also buy the fillets through Revo’s online store. With about one in four of the world’s freshwater fish at risk of extinction, the near future could see an increasing number of consumers looking for more conscience-free alternatives.

The nutritional arguments for different protein sources are also strong, says Simsa. Not only do Revo Foods salmon fillets have a high omega-3 fatty acid content due to the microalgae oil, the fermented mushroom protein also does not contain any microplastics and has a higher bioavailability than beef, meaning a larger percentage of it enters the body’s systemic circulation. If grilled, the “inspired by salmon” fillets contain no cholesterol, histamines or antibiotics, promises Simsa.

The commercial launch of the salmon fillets allowed Revo Foods to open the biggest 3D food manufacturing facility in the world in Vienna in September 2024, the Taste Factory, a coup for Simsa who spotted a niche in the market for fish steaks when researching cell-based meat during his doctorate in biotechnology. “I saw that there were a fair few companies focused on meat alternatives like beef and chicken, but hardly anyone was looking at fish and seafood,” he recalls.

Simsa sees the “inspired by salmon” as a “hero product” to showcase the realistic looking fish alternatives his company can produce (alongside its salmon and tuna-tasting spreads) before adding other products to its range. Revo Foods is currently part of a 13.9 million euro pan-European project, Like-a-Pro, which includes chefs, growers, retailers and other food producers developing and trialling 16 new alternative protein products based on seven sustainable, healthy and novel sources.

Funding for research and development for the alternative protein sector has proved crucial because it involves changing generations-old systems and habits of food production and consumption, which makes raising capital challenging.

Simsa is confident the market share of meat alternatives will grow. “In the food industry, the meat market is worth 1.4 trillion dollars, so alternative proteins have the potential to be a massive industry, even if they only take up a fraction of that market,” calculates Simsa.

The meat substitute market was valued at 10 billion dollars in 2021 and sales were projected to grow at 34% compound annual growth rate to 235 billion dollars by 2032, with mycoprotein meat substitutes reflecting the highest growth.

In terms of fish specifically, Revo Foods’ fish alternatives could take a bite out of a 677-billion-dollar fish and seafood market. The Austrian company could benefit from a growing worldwide demand for fish, given global catches have declined by 1% since the 1990s and harvesting and farming licences for popular species like salmon can be hard to secure.

“This is not necessarily about ending the eating of meat and fish, but we need to diversify our sources of protein,” says Simsa. “The meat industry as it is now has existed for hundreds of years and receives massive governmental subsidies. The industry for protein diversification is young, but we are growing.”

Were you inspired by this story and have a project idea you want to realise?

Through our funding programmes, national/regional funding bodies support SMEs, large companies, universities and research organisations conducting R&D and innovation projects together beyond borders to achieve great results. Learn more about our programmes and discover whether we have a funding opportunity for your organisation.

Eureka programme and project name: Eurostars-3 M3DS

Countries involved: Austria, Sweden

Project duration: 2023-2024

Eureka programme and project name: Eurostars-3 MYOSEA-3D

Countries involved: Austria, Belgium

Project duration: 2024-2026